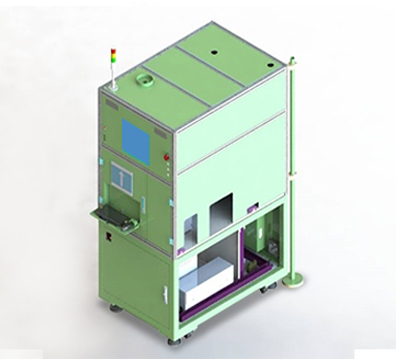

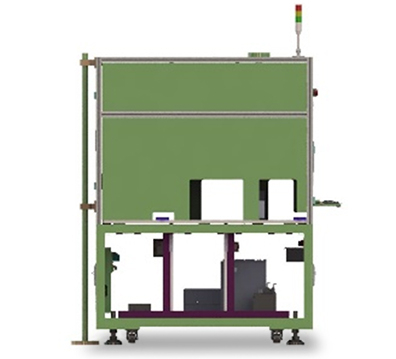

Motor automatic welding machine

Model: spot welding machine

Function: Automatic welding motor parts

Advantages:

1. High precision, high efficiency.

2. High yield, high stability.

3. With automatic detection function;

4. High intelligent real-time monitoring

After the equipment is energized and aerated, the motor and the carrier are placed on the external flow line manually. When the carrier flows to the welding station, the carrier is positioned and the parts to be welded are clamped. Visual capture and position to the welding point, guide the welder to complete the welding, and finally recheck the welding point to eliminate bad. According to customer needs with other stand-alone free combination into an automated production line.

Equipment size: 1000mm*1500mm*2000mm

Rated voltage: 220V

Rated power: 1.0KVA

Gas supply: 0.5~0.7Mpa

1. CCD visual guide welding, product welding high precision, high efficiency

2. Automatically clamp welded parts, effectively avoid virtual welding, equipment yield is high

3. Motion control and vision system cooperate to effectively eliminate bad incoming materials and monitor bad production

4. The equipment is highly intelligent and can automatically generate data reports